When managers tour a site once or twice a week, the camera on their head captures video footage of the whole project and uploads it to image recognition software, which compares the status of many thousands of objects on site—such as electrical sockets and bathroom fittings—with a digital replica of the building.

The AI also uses the video feed to track where the camera is in the building to within a few centimeters so that it can identify the exact location of the objects in each frame. The system can track the status of around 150,000 objects several times a week, says Danon. For each object the AI can tell which of three or four states it is in, from not yet begun to fully installed.

Site inspections are slow and tedious, says Sophie Morris at Buildots, a civil engineer who used to work in construction before joining the company. The Buildots AI gets rid of many repetitive tasks and lets people focus on important decisions. “That’s the job people want to be doing—not having to go and check if the walls have been painted or if someone’s drilled too many holes in the ceiling,” she says.

Another plus is the way the tech works in the background. “It captures data without the need to walk the site with spreadsheets or schedules,” says Glen Roberts, operations director at Wates. He says his firm is now planning to roll out the Buildots system at other sites.

Comparing the complete status of a project with its digital plan several times a week has also made a big difference during the covid-19 pandemic. When construction sites were shut down to all but the most essential on-site workers, managers on several Buildots projects were able to keep tabs on progress remotely.

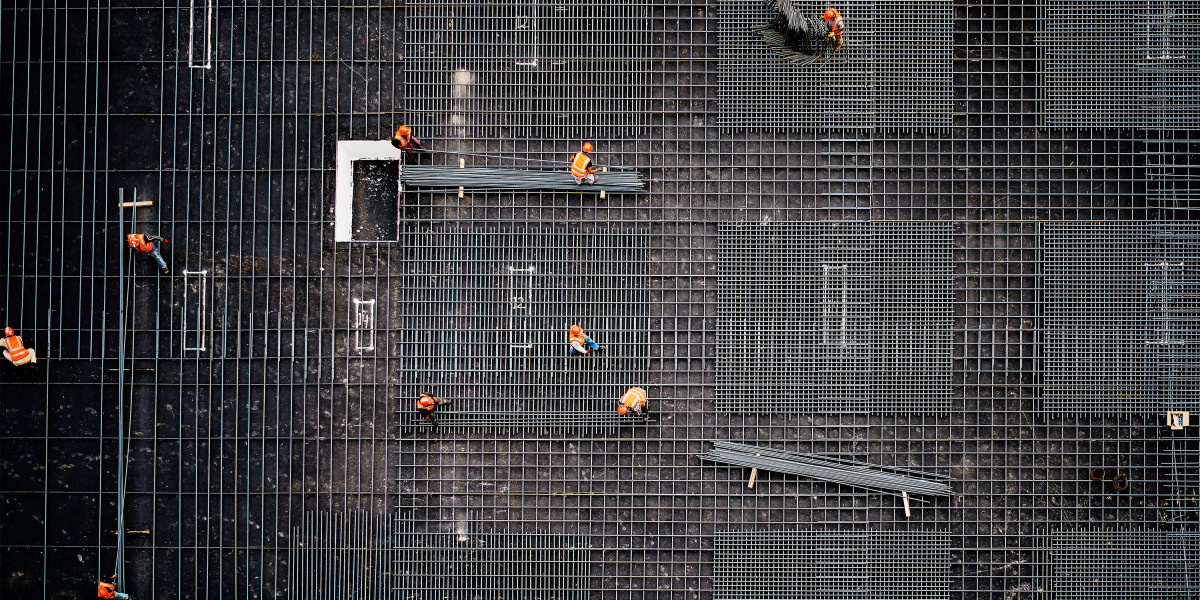

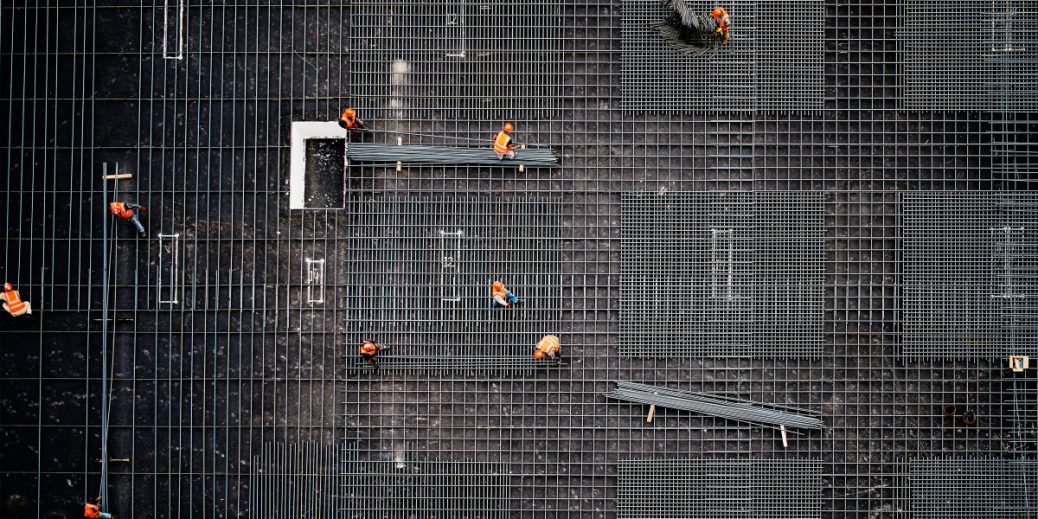

But AI won’t be replacing those essential workers anytime soon. Buildings are still built by people. “At the end of the day, this is a very labor-driven industry, and that won’t change,” says Morris.

Change note: we have changed the text to clarify how the Buildots system differs from others.

Recent Comments