You might think the meals that end up in the grocery store’s frozen aisle, at Starbucks, or on airplanes are robot-packed already, but that’s rarely the case. Workers are often much more flexible than robots and can handle production lines that frequently rotate recipes. Not only that, but certain ingredients, like rice or shredded cheese, are hard to portion out with robotic arms. That means the vast majority of meals from recognizable brands are still typically hand-packed.

However, advancements from AI have changed the calculus, making robots more useful on production lines, says David Griego, senior director of engineering at Amy’s.

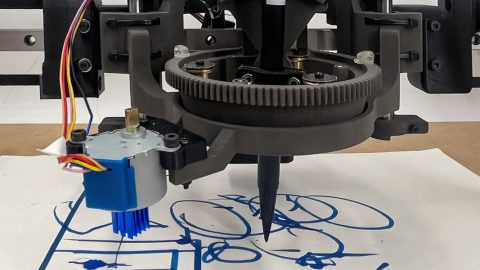

“Before Silicon Valley got involved, the industry was much more about ‘Okay, we’re gonna program—a robot is gonna do this and do this only,’” he says. For a brand with so many different meals, that wasn’t very helpful. But the robots Griego is now able to add to the production line can learn how scooping a portion of peas is different from scooping cauliflower, and they can improve their accuracy for next time. “It’s astounding just how they can adapt to all the different types of ingredients that we use,” he says. Meal-packing robots suddenly make much more financial sense.

Rather than selling the machines outright, Chef uses a service model, where customers pay a yearly fee that covers maintenance and training. Amy’s currently uses eight systems (each with two robotic arms) spread across two of its plants. One of these systems can now do the work of two to four workers depending on which ingredients are being packed, Griego says. The robots also reduce waste, since they can pack more consistent portions than their human counterparts. One-arm systems typically cost less than $135,000 per year, according to Chef CEO Rajat Bhageria.

With these advantages in mind, Griego imagines the robots handling more and more of the meal assembly process. “I have a vision,” he says, “where the only thing people would do is run the systems.” They’d make sure the hoppers of ingredients and packaging materials were full, for example, and the robots would do the rest.

Robot chefs have been getting more skilled in recent years thanks to AI, and some companies have promised that burger-flipping and nugget-frying robots can provide cost savings to restaurants. But much of this technology has seen little adoption in the restaurant industry so far, says Bhageria. That’s because fast-casual restaurants often only need one cook running the grill, and if a robot cannot fully replace that person because it still needs supervision, it makes little sense to use it. Packaged meal companies, however, have a larger source of labor costs that they want to bring down: plating and assembly.

“That’s going to be the highest bang for our buck for our customers,” Bhageria says.

CHEF

The notion that more flexible robots could mean broader adoption in new industries is no surprise, says Lerrel Pinto, who leads the General-Purpose Robotics and AI Lab at New York University and is not involved with Chef or Amy’s Kitchen.

Recent Comments